Your Full-Service Fabrication Partner

At National Tube Processing, we offer comprehensive metal fabrication solutions that cover every stage of your project lifecycle, from design and engineering assistance through precise fabrication, assembly, finishing, and delivery. Our services utilize advanced technologies, including sheet & tube laser cutting, CNC machining, forming & welding, as well as finishing treatments such as anodizing, plating, silk screening and powder coating. We are committed to delivering high-quality, custom metal products tailored to the unique needs of our clients and industries, ensuring optimal value in all phases of the client-manufacturer relationship.

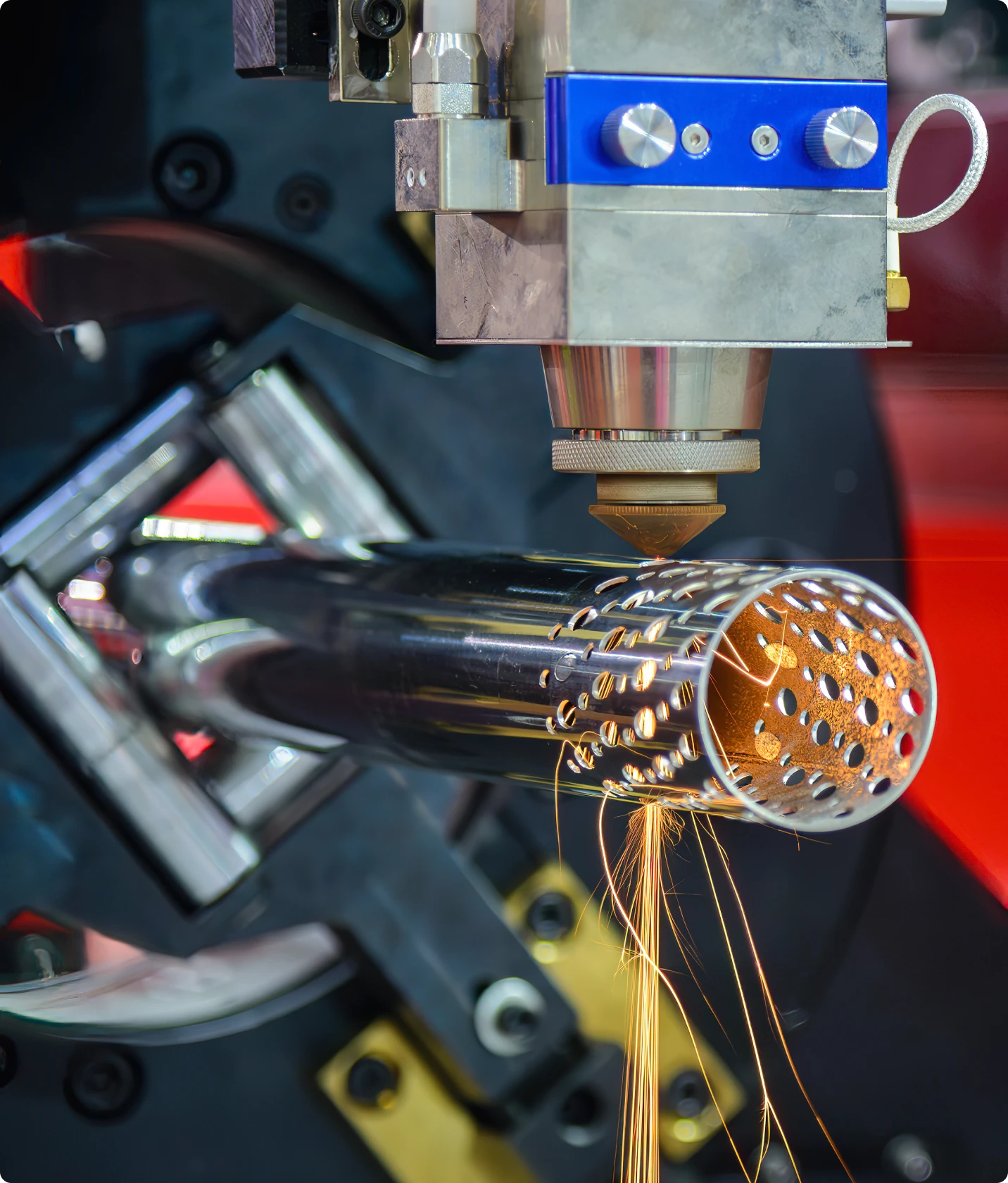

Our cutting services use advanced laser and plasma technologies to achieve outstanding accuracy and efficiency. Whether your needs involve intricate patterns or large-scale production, we deliver clean cuts and precise dimensions across various materials and thicknesses, consistently meeting the standards of multiple industry sectors. Our team collaborates closely with clients to optimize process parameters for each material, ensuring minimal waste and cost-effective solutions.

- High-precision sheet & tube laser and cutting & etching for complex shapes and tight tolerances

- Capable of processing various metals including aluminum, steel, stainless, brass or bronze

- A variety of finishing options, including powder coating, deburring, and sandblasting

- Rapid turnaround times to meet critical project deadlines

- Scalable solutions for small prototypes to large-scale production runs

- Cost-effective nesting and material utilization to minimize waste

We specialize in custom metal fabrication, transferring your concepts into reality with expert craftsmanship. From robust structural components to intricate, specialized assemblies, our team collaborates closely with you to deliver solutions that meet your exact specifications. Each project is approached with a commitment to accuracy, and innovation, ensuring that every finished part upholds the highest standards of quality and performance.

- Transforming raw materials into precision-crafted components and products for any industry.

- Full-service fabrication including forming, welding and assembly

- Expertise in working with diverse metals and alloys

- Effective quality control to ensure consistent, high-quality results

- Efficient management and production processes ensure your products are delivered on schedule

- You get a partner with decades of experience, industry expertise and a strong track record

National Tube Processing delivers expert solutions as your trusted one-stop fabrication shop. Our comprehensive approach ensures that every project is handled with attention to detail from start to finish. With cutting-edge technology and skilled craftsmanship, we offer custom tailored services with high-quality results and efficient delivery second to none.

Utilizing state-of-the-art lasers, we provide high-speed, high precision cutting for complex shapes and intricate designs with minimal waste.

Expert etching services, designed to create precise markings across multiple materials. Ideal for labeling, branding, inventory control, and elevating your product’s visual appeal.

Machining services include precise cutting, drilling, milling, and turning to create custom parts and assemblies. Using advanced equipment, we ensure accurate results and reliable performance.

Our skilled welders are experts in both Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG) welding processes, offering versatility and precision for all your various welding needs

Our advanced forming processes shape metal with precision, using CNC press brakes to create consistent, accurate components for custom applications.

Expert finishing services including powder coating, painting, plating, anodizing, silk screening, deburring, and vibratory finishing—all under one roof.

National Tube Processing is a leading fabrication facility specializing in high-quality metalworking services. Utilizing state-of-the-art technology and expert craftsmanship, we collaborate with clients across the country to realize their concepts, delivering projects with efficiency and precision while upholding rigorous standards of excellence.

- Full-Service Fabrication: laser cutting, forming, welding, finishes & assembly

Our advanced technology and skilled team ensure every cut, bend, and weld meets exact specifications, delivering flawless components for your project.

- Comprehensive Solutions

As a one-stop shop, we handle every stage of fabrication – from assistance in design & engineering, to final delivery – streamlining your process and saving you time and resources.

- Cutting-Edge Technology

Equipped with state-of-the-art laser cutting, CNC forming and welding systems, we provide innovative solutions for projects of any size or complexity.

- Nationwide Reliability

With efficient logistics and a commitment to on-time delivery, we serve clients all across the country ensuring your projects stay on track every time.

We partner with a diverse range of industries and businesses, from small prototyping firms to large-scale manufacturers, who require high-quality precision metal fabrication. Our expertise supports companies in sectors such as heavy equipment, energy, automotive, construction, and many others, delivering reliable components and solutions critical to their success. By collaborating closely with our clients, we ensure that every project meets their specific requirements and industry standards.

Delivering high quality components to streamline production processes and significantly enhance overall product performance for our clients.

Retailers, restauranters and architects bring their ideas to life through custom fabricated metal & wood fixtures.

Producing specialized parts with exact specification, ensuring seamless integration into equipment and systems with fast reliable delivery.

Our sheet & tube laser and lathe equipment are ideal for machining precision parts with tight tolerances and the ability to cut up to 1″ steel plate.

How to get started

Submit project information for a customized quote

For questions or general inquires